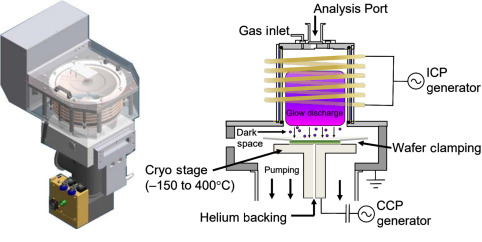

Electrical motor design is a complex process that requires a deep understanding of electromagnetic theory, materials science, and mechanical engineering. Multiphysics simulation technologies such as FEA, CFD, and electromagnetic simulation software can greatly aid in the design and analysis of electric motors.

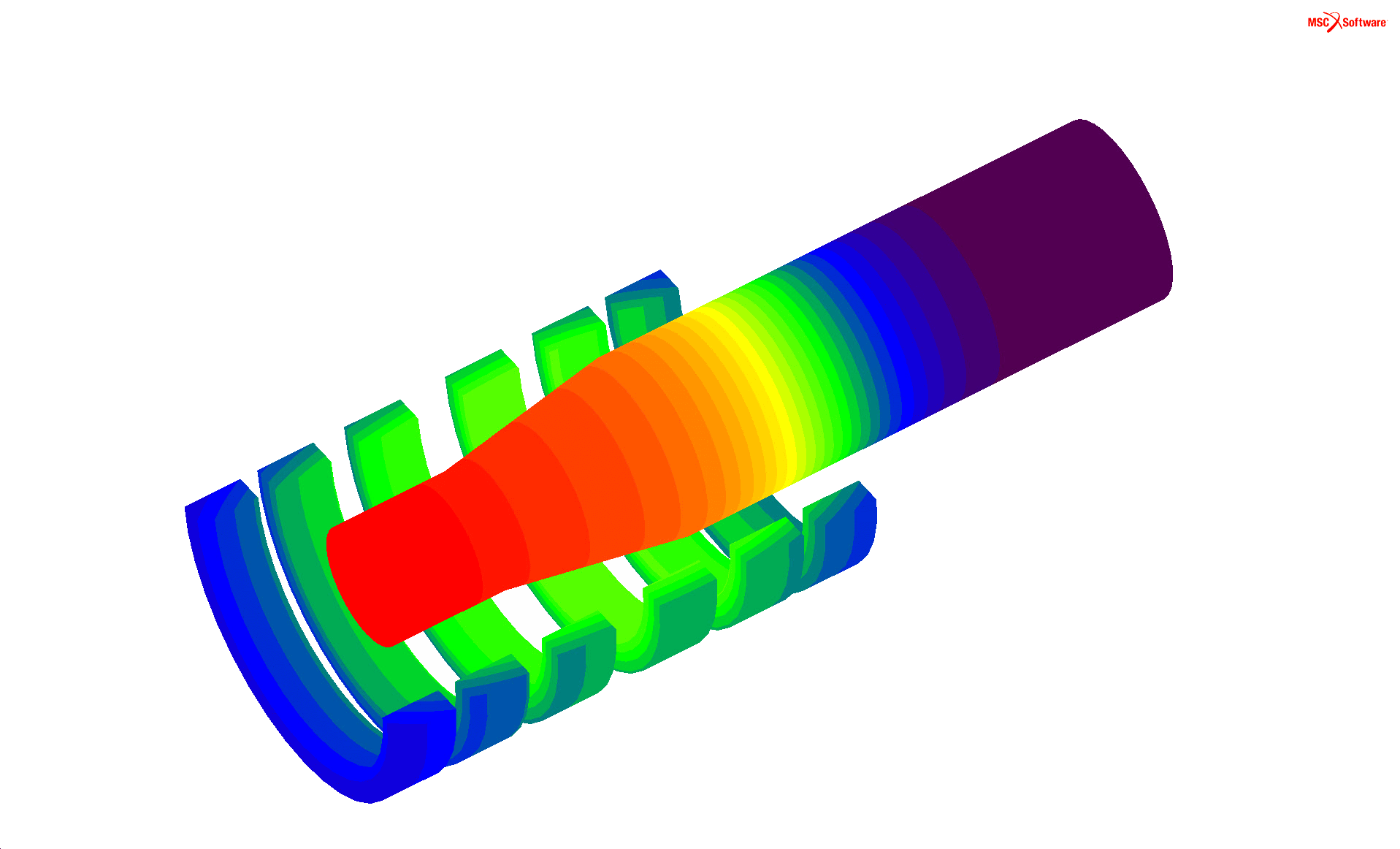

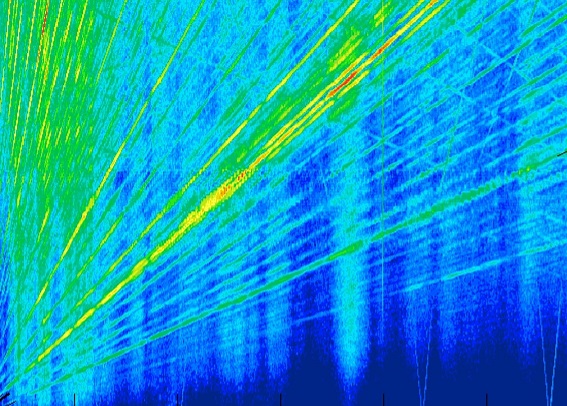

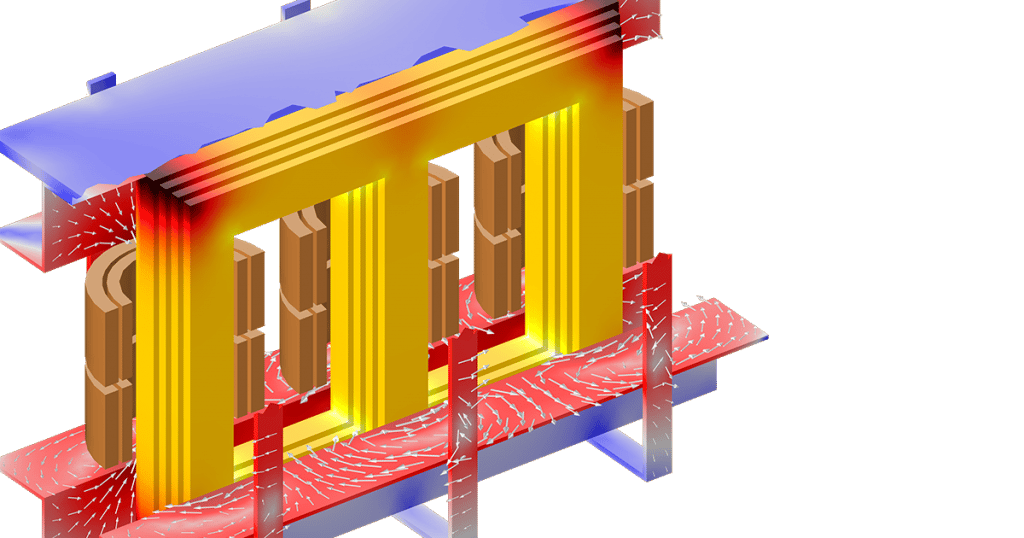

These simulation tools can be used to evaluate the basic characteristics of electric motors such as induced voltage, torque, and inductance, as well as more complex phenomena such as thermal demagnetization and vibration. By using these tools, our engineers can optimize the motor design for performance, efficiency, and reliability.

Induced voltage, load torque, cogging torque, inductance, flux linkage, iron losses, coil losses, magnet loss, permeance, parameter sensitivity, and equivalent circuit model extraction are all key parameters that can be analyzed and optimized using multiphysics simulation technologies. These parameters are crucial for designing motors that meet specific performance requirements and operate efficiently over a wide range of operating conditions.

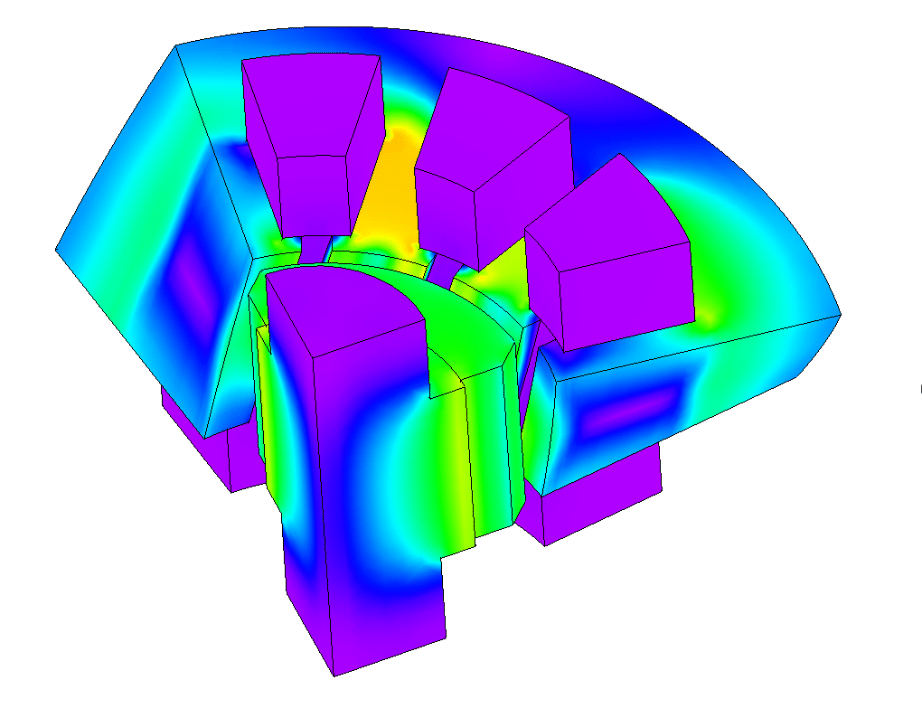

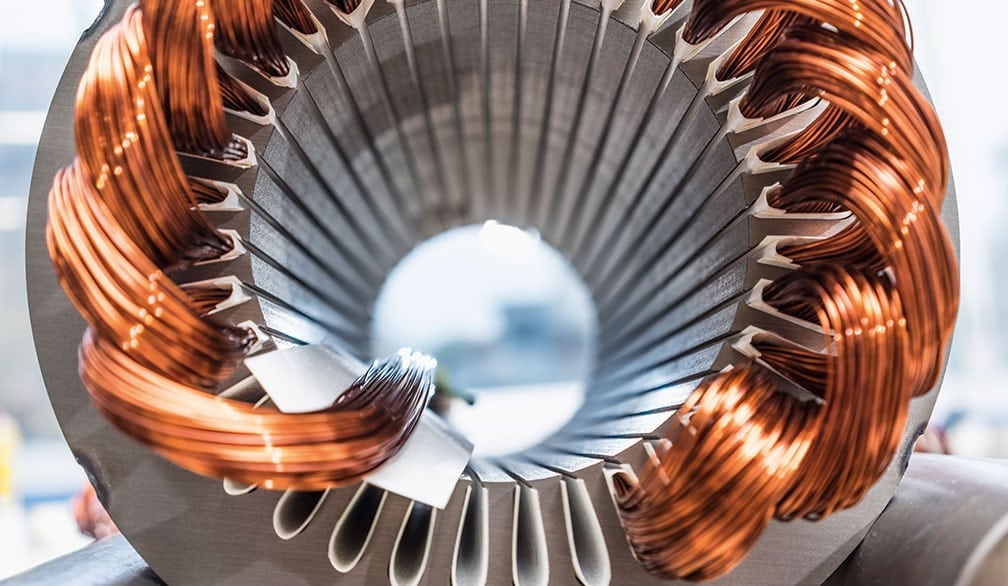

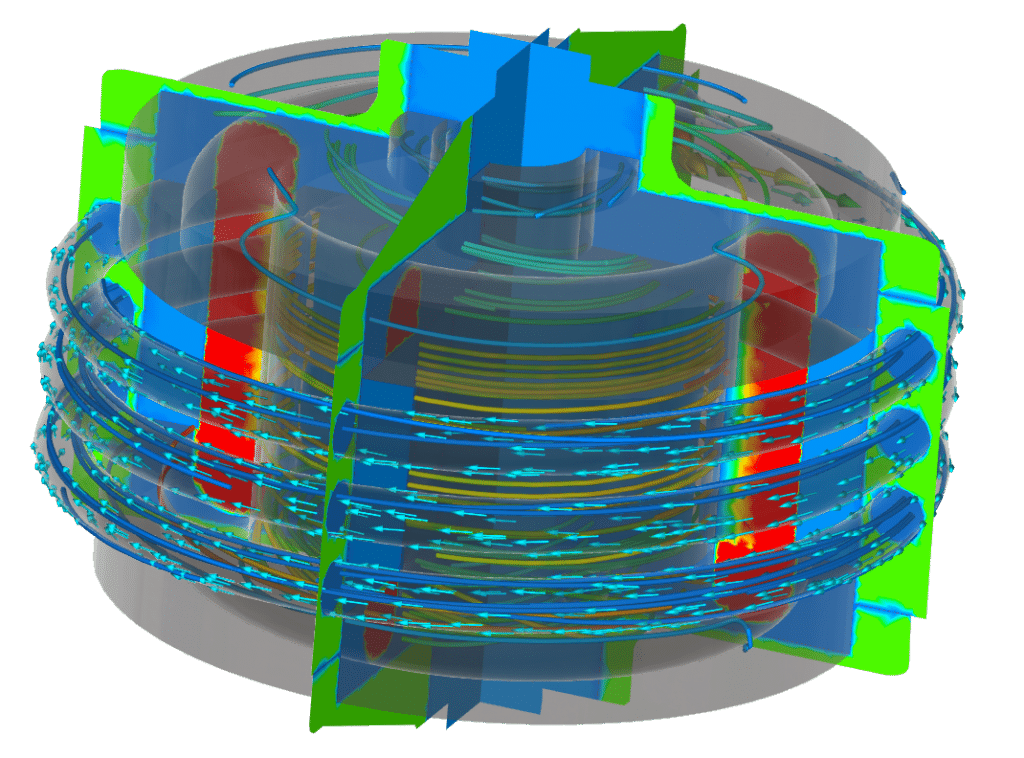

In addition to basic motor characteristics, multiphysics simulation technologies can also be used to analyze the effects of various design parameters such as rotor/stator geometry, magnet placement, and winding configuration on motor performance. By analyzing these parameters, our designers can optimize the motor design to meet specific performance requirements, such as high torque, high efficiency, or low noise.